Sanitary-Grade Pneumatic Ball Valves from Zhongyuan Automatic Control can be connected via flanges. How do they differ from general pneumatic ball valves?

Zhongyuan’s sanitary-grade pneumatic ball valves are manufactured using stainless steel 304SS or 316L, with standard electropolishing to ensure a smooth, clean surface free from media retention areas and potential contamination. These valves meet the stringent requirements of the food, biopharmaceutical, and daily chemical industries for handling specialized media. Their smooth, seamless design and automatic drainage features also make them ideal for steam-in-place (SIP) and clean-in-place (CIP) processes. Connection methods for sanitary-grade valves include threaded, flanged, welded, clamp, or ferrule fittings, depending on engineering requirements.

Key Differences Between Sanitary-Grade and General Pneumatic Ball Valves:

Material

Sanitary-grade valves: Only 304SS, 304L, 316, or 316L stainless steel are used, with special post-processing treatments to meet hygiene standards.

General industrial valves: Materials include cast iron, cast steel, ductile iron, or copper alloys, which are unsuitable for sanitary applications.

Why: Sanitary-grade valves are used in pharmaceutical, food, and chemical industries where products are consumed or directly contact the human body. Materials like steel, iron, or copper corrode or rust in humid environments, contaminating products. Copper valves are particularly problematic due to toxic copper oxide formation.

Surface Finish

Sanitary-grade valves: Feature electropolished surfaces to eliminate contamination risks and ensure easy cleaning.

General industrial valves: Prioritize high-temperature/pressure resistance, durability, and operational flexibility, with less emphasis on surface aesthetics or hygiene.

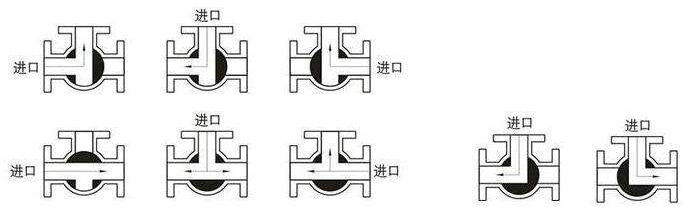

Connection Methods

Sanitary-grade valves: Typically use clamp quick-connect or threaded fittings for rapid disassembly and cleaning.

General industrial valves: Employ flanged, threaded, welded, or quick-connect methods based on operational needs.